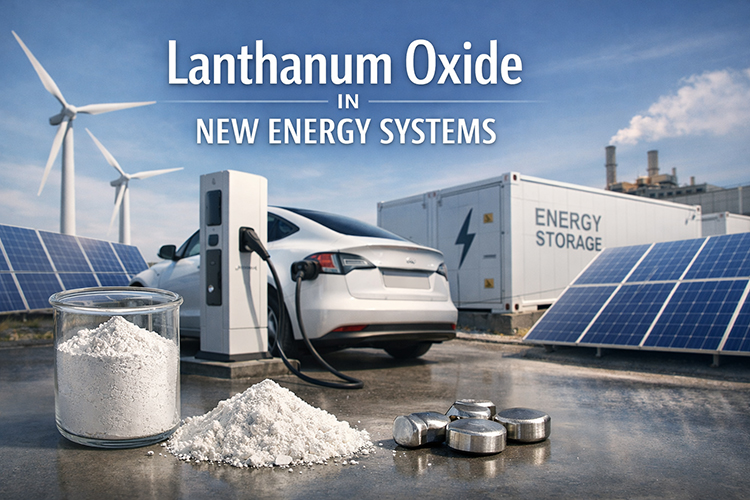

Lanthanum is a rare earth element known for its useful chemical and physical traits. Its compounds lead to many practical applications. Not only do they help in energy and advanced materials, but they also improve everyday technology. Some of the common compounds of lanthanum include:

Each one of these compounds has a unique benefit. Their traits, such as high temperature resistance and a good refractive index, help them fit important roles in industry.

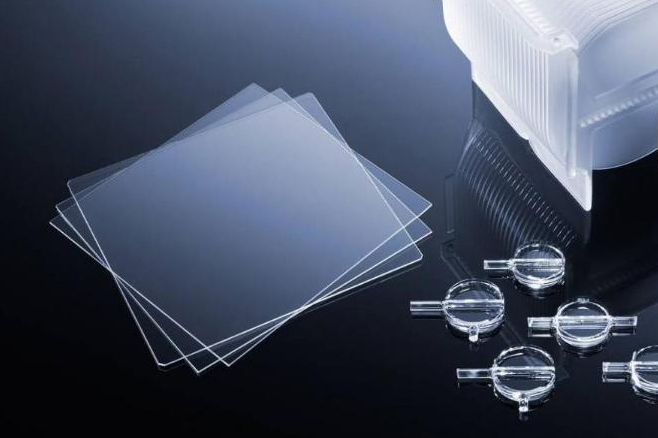

Lanthanum oxide stands out because of its clear optical qualities and strong stability when heat is applied. In the lab and factory, this oxide is mixed into different glasses. Camera lenses, telescope glasses, and fiber optics often include lanthanum oxide because its high refractive index helps bend light better and produce sharper images. I recall a research center where they used a blend with around 5-10% lanthanum oxide to improve the performance of optical fibers used in telecommunications. Moreover, fuel cell researchers often use this compound to help keep the reaction chambers free of impurities, improving overall efficiency.

In the petroleum sector, the use of lanthanum oxide has improved the process that converts heavy crude oil into lighter fuels like gasoline and diesel. When added in small amounts, it speeds up the cracking process. This small addition can lead to improved yields and a smoother process overall.

Lanthanum carbonate is well known in the field of medicine, especially for helping patients with high phosphate levels due to kidney problems. In many hospitals, doctors have used controlled doses of this compound to help lower phosphate in patients' blood. This treatment results in improved outcomes and easier management of the condition. Our understanding of its benefits has grown over years of careful study.

Outside the hospital, lanthanum carbonate has found its way into water treatment systems. Municipal water plants have tried using small amounts of this compound to reduce leftover phosphates in water. In one well-documented case, a town managed to lower phosphate levels significantly after including lanthanum carbonate in their cleanup process. The end result was a better quality of water for the local community. This method has become a preferred option in several regions facing water quality challenges.

Lanthanum nitrate is a key ingredient when people aim to improve the strength and clarity of glass used in modern devices. In many glass manufacturing plants, a calculated percentage of lanthanum nitrate is mixed in during the glass-making process. This adjustment helps boost both the optical performance and the ability of the glass to handle high temperatures. Fiber optic cables, laser components, and even parts of telecommunication devices benefit from the enhanced glass properties that stem from this compound. In one specific case, a manufacturer showed improved thermal resistance by adding about 3-5% of lanthanum nitrate into the glass batch. The result was a more durable and reliable product suitable for high-temperature environments.

Lanthanum acetate is often used when a chemical reaction must run smoothly. In laboratories and production facilities, it helps in refining ceramic materials. Over the years, it has been seen that ceramics with added lanthanum acetate have better strength and durability. This improvement allows the ceramic parts to be used in tougher conditions, such as in aerospace components or in medical devices. When crafting new materials, scientists sometimes turn to lanthanum acetate as a small catalyst. Its role can help bond ingredients together better and even speed up the synthesis process. In practical terms, this means stronger and longer-lasting advanced materials that meet the high standards of today's industries.

Lanthanum compounds serve an important purpose in the world of modern technology. Their unique physical and chemical features keep them in demand across many fields. From enhancing optical clarity and speeding up industrial processes to improving patient care and cleaning water supplies, these compounds are truly versatile. They simplify operations and lead to energy-efficient solutions that the industry values highly.

In a practical workshop or a high-tech laboratory, small tweaks using these materials lead to significant improvements. As industries seek more reliable and sustainable solutions, lanthanum's straightforward properties show that even simple elements can provide smart answers.

For those looking for high-purity lanthanum compounds to support your projects—whether for specialty glass work, advanced ceramics, or health-related applications—Stanford Materials Corporation (SMC) stands as a trusted supplier. Their long-standing reputation and commitment to quality assure that each product meets the lofty standards demanded by today's engineers and scientists.

Eric Loewen

Eric Loewen graduated from the University of Illinois studying applied chemistry. His educational background gives him a broad base from which to approach many topics. He has been working with topics about advanced materials for over 5 years at Stanford Materials Corporation (SMC). His main purpose in writing these articles is to provide a free, yet quality resource for readers. He welcomes feedback on typos, errors, or differences in opinion that readers come across.

Inquiry List

Inquiry List