Abstract: In the relentless drive for lightweighting across automotive, aerospace, and 3C, magnesium is the clear frontier. But pure magnesium is weak. The leap to a structural material happens only when specific rare earths—Neodymium, Yttrium, Cerium—enter the mix. This article breaks down how these elements don't just mix in; they actively re-engineer the metal's internal architecture. We’ll explain the distinct role of each rare earth, contrast the sourcing routes that guarantee (or gamble) performance, and outline why the choice between pure metals and a master alloy is the most critical procurement decision for lightweight success.

For any component—be it an EV motor housing, a satellite bracket, or a laptop chassis—the mechanical load is the ultimate inspector. Gaining 30% weight savings over aluminum means nothing if the part distorts under heat or fails in vibration. The goal isn’t just a lighter box; it’s about achieving two simultaneous outcomes:

Specific Strength: A strength-to-weight ratio that surpasses aluminum alloys, enabling true design freedom.

Functional Reliability: Stability at elevated temperatures (creep resistance), good ductility, and consistent behavior batch-to-batch.

Traditional solutions like heavier steels or even standard aluminum castings hit a wall. This is where the strategic addition of rare earths changes the game completely. They don't sit passively in the melt; they force a new microstructure.

Calling rare earths “alloying elements” misses the point. Their value is in phase-forming and grain-refining—actions that physically rebuild the magnesium. Compare the mechanism to common alternatives:

1. Aluminum in Magnesium (e.g., AZ91): Primarily solid-solution strengthening. It’s a basic upgrade, offering modest improvements but poor creep performance above 120°C and limited ductility. It’s the incumbent, not the innovator.

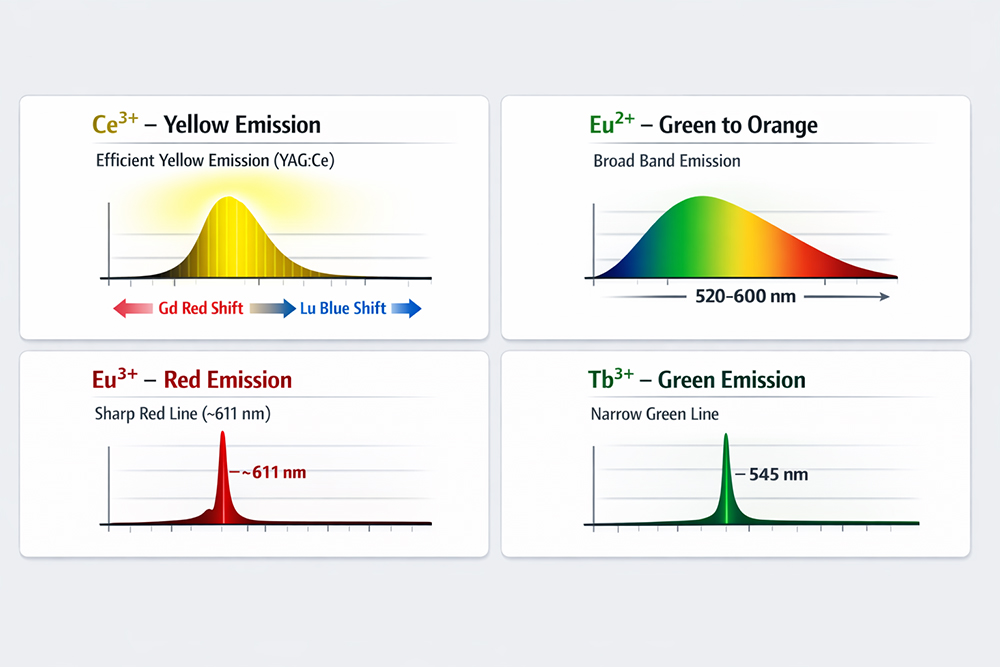

2. Rare Earths in Magnesium (Nd, Y, Ce): This is where the engineering happens.

Neodymium (Nd): It doesn’t just dissolve. It forms distinct, nanoscale intermetallic compounds (Mg₁₂Nd) that act like immutable internal scaffolding. These particles block dislocation movement and pin grain boundaries rigidly, even at high heat.

Result: Dramatically increased tensile/yield strength and best-in-class creep resistance. This is why Nd is non-negotiable for powertrain components.

Yttrium (Y): It achieves profound solid-solution strengthening and, critically, forms a stable, self-healing oxide layer on the surface.

Result: The highest specific strength of any Mg alloy series and corrosion resistance that opens up military and aerospace applications.

Cerium (Ce) / Mischmetal: Its superpower is transformation during solidification. It drastically refines the cast grain structure.

Result: A finer, more uniform grain network means better ductility, fewer casting defects (hot tears), and improved pressure tightness. It makes complex, thin-wall die-castings viable.

This is the pivot point. You need Nd in your alloy. How do you get it there? The industry’s two paths have vastly different implications for cost, risk, and yield.

| Sourcing Consideration | The Pure Metal Route (Mg + Nd Metal) | The Master Alloy Route (Mg-20%Nd Ingot) |

|---|---|---|

| Process at Foundry | Alloying. Must melt, mix, and homogenize two reactive metals. High oxidation loss of expensive Nd. | Melting. Simply re-melt a single, homogeneous material. Oxidation loss is negligible. |

| Chemistry Control | Variable. Agitation, temperature, and time create melt-to-melt variance. Final Nd content is an estimate. | Fixed. The Nd percentage (e.g., 20%) is certified and uniform throughout the ingot. It is a known input. |

| Key Risk | Performance scatter. Inconsistent Nd content leads to variable strength and creep life in final castings. | Minimal. Delivers a repeatable, predictable foundation for properties. Eliminates a major scrap driver. |

| Total Cost Driver | Apparent low material cost, hidden high processing cost. Losses, energy, scrap, and QA overhead add up. | Higher material cost, lower conversion cost. Pays for precision upfront to ensure manufacturing efficiency. |

The master alloy route isn’t paying more for magnesium; it’s paying to outsource the risk and complexity of high-precision alloying to a specialist supplier.

This is where a supplier like Stanford Materials Corporation (SMC) shifts from vendor to engineering partner. Our focus isn’t on selling neodymium metal; it’s on delivering neodymium that is guaranteed to form Mg₁₂Nd.

We control the process so that the rare earth element arrives at your foundry in its optimal state—perfectly dissolved, homogenized, and ready to perform its structural role upon solidification. Our Certificates of Analysis (CoA) are therefore not just purity reports; they are predictive performance documents. A tight tolerance on Nd content (e.g., 20.0% ± 0.3%) directly correlates to predictable mechanical properties in your finished part.

For the procurement professional, this translates to a simplified equation: one reliable material input replaces multiple uncertain ones. It removes a major variable from your supply chain, turning a critical performance parameter from a question into a guarantee.

The shift from “lightweight” to “lightweight-and-strong” isn’t a gradual improvement—it’s a step-function enabled by rare earth elements. In this context, the raw material is a foundational component of your product’s performance, not a bulk commodity.

A magnesium rare earth master alloy, with its pre-engineered chemistry, is the only sourcing choice that consistently bridges the gap between an ambitious design spec and a reliably manufacturable component. Choosing a supplier that masters this metallurgy isn’t just about buying a better ingot; it’s about investing in higher yields, fewer engineering validations, and components that perform to their theoretical limits on the first run.

Ready to see how the right master alloy can engineer performance into your next lightweight design?

Contact us to receive our technical dossier “Mg-RE Master Alloys for Specific Performance Outcomes” and discuss a sample matched to your application. Let our materials engineers show you the data behind predictable performance.

Eric Loewen

Eric Loewen graduated from the University of Illinois studying applied chemistry. His educational background gives him a broad base from which to approach many topics. He has been working with topics about advanced materials for over 5 years at Stanford Materials Corporation (SMC). His main purpose in writing these articles is to provide a free, yet quality resource for readers. He welcomes feedback on typos, errors, or differences in opinion that readers come across.