Abstract: In the world of precision optics, the final surface finish is everything. As demands evolve from smartphone cameras to augmented reality waveguides, achieving sub-nanometer smoothness without subsurface damage defines manufacturing success. This article explains why high-purity cerium oxide (CeO₂) polishing powder has become the undisputed industry standard, outperforming legacy abrasives like rouge and zirconia. We’ll break down its unique action, guide selection based on glass type and polishing stage, and outline the critical quality parameters that separate effective powder from mediocre filler.

Why Optics Demand Atomic-Level Perfection

For any optical component—be it a humble camera lens or a complex AR glass waveguide—light is the ultimate inspector. Surface irregularities, even those measured in angstroms (Å), scatter light. This scattering translates directly into measurable losses: reduced contrast, flare, ghosting, and a drop in overall system resolution and efficiency.

The goal isn’t just a surface that looks smooth. It’s about achieving two simultaneous outcomes:

-

Extreme Surface Smoothness: A final surface roughness (Ra) consistently below 1 nanometer, often targeting Ra < 0.5 nm for high-end applications.

-

Minimal Subsurface Damage (SSD): The polishing process must remove material without introducing micro-cracks or a stressed layer beneath the surface. This damaged layer can later relieve stress, causing the surface figure to drift over time or under thermal cycling, ruining the optical path.

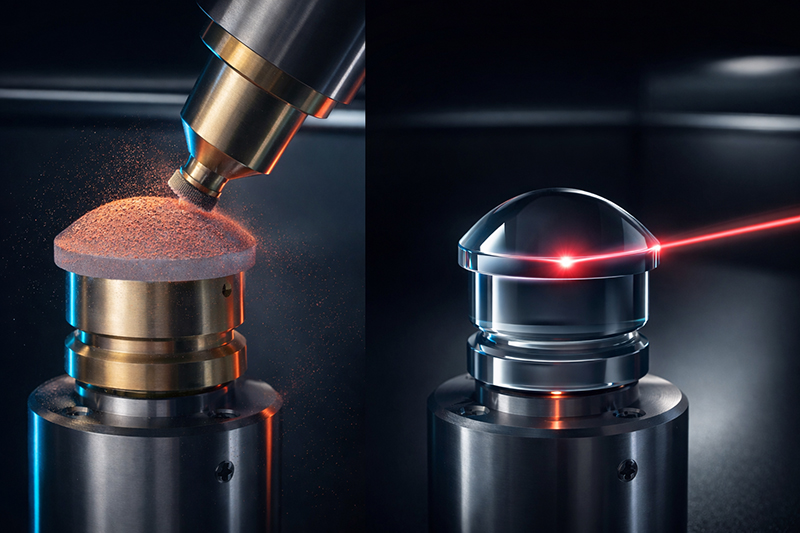

Traditional mechanical grinding and even some abrasive polishes excel at removal rates but fail catastrophically on the second count, leaving a damaged “skin” on the glass. This is where the chemistry of ceria makes the difference.

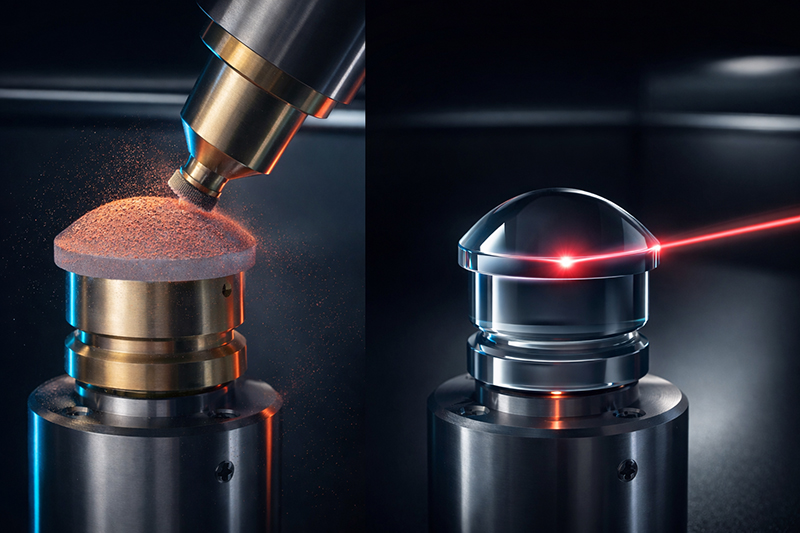

Beyond Abrasion: The Chemical-Mechanical Edge of Ceria

Calling ceria a mere “abrasive” misses the point. Its dominance stems from a synergistic chemical-mechanical polishing (CMP) action that other powders can’t match. Let’s compare it to the old standards:

-

Iron Oxide (Rouge / “Red Powder”): The traditional choice. It’s a pure mechanical abrasive. Its irregular, often angular particles scratch and fracture the glass surface to remove material. While it can achieve a fine finish, it inevitably leaves a significant subsurface damaged layer and tends to embed stains in the glass that are notoriously difficult to clean. Its removal rate is also relatively slow.

-

Zirconium Oxide (ZrO₂): Harder and more aggressive than rouge. It offers a faster mechanical removal rate but at a steep cost: a high risk of introducing scratches and deeper subsurface damage. It’s a blunt instrument, useful for very rough shaping but detrimental for achieving the final, defect-free surface required for imaging.

-

Cerium Oxide (CeO₂): This is where the magic happens. Ceria particles interact with the silica (SiO₂) network of the glass surface on a chemical level. The cerium ions have a high affinity for the silicate matrix, forming a transient, softened reaction layer. The mechanical action of the polishing pad then easily shears this softened layer away.

- Result 1: High, Stable Removal Rate. The chemical reaction accelerates material removal compared to pure mechanical abrasion.

- Result 2: Superior Surface Integrity. Because material is removed via shearing a weakened layer rather than fracturing hard glass, the resulting surface has exceptionally low roughness and virtually no subsurface damage.

- Result 3: Cleanability. The reaction products are typically water-soluble, meaning ceria slurry rinses off cleanly without staining or embedding.

A Practical Selection Guide

Not all ceria is created equal. Selecting the right grade is critical for efficiency and finish.

| Polishing Stage / Glass Type |

Key Objective |

Recommended Ceria Powder Grade |

Rationale |

| Rough Polishing / Molding Defect Removal |

High removal rate, shape correction |

Coarse Grade (e.g., F-grained) – Larger particle size (D50 ~ 3-5 µm). Standard purity. |

Maximizes speed of material removal to quickly achieve desired surface figure. Cost-effective. |

| Fine Polishing / Standard Lenses (K9, BK7) |

Achieving final surface figure and smoothness |

Fine Precision Grade (e.g., P-series) – Controlled, sub-micron particle size (D50 ~ 0.8-1.5 µm). High purity (>99.9%). |

Balances good removal rate with the ability to achieve Ra < 1 nm. High purity prevents contamination. |

| Ultra-Fine Finishing / Fused Silica, AR Glass |

Achieving ultimate low Ra (<0.5 nm) & zero SSD |

High-Purity Colloidal Grade – Nano-sized particles (D50 < 0.5 µm) in stable suspension. Highest purity (99.99%+). |

Nano-particles prevent microscratches. Colloidal stability ensures uniform polishing action. Essential for laser-grade and waveguide optics. |

What Defines True Quality in Ceria Powder

When you evaluate a ceria powder, the datasheet numbers only tell part of the story. The processing and morphology are what determine consistency on your production line.

- Controlled Hardness: Ceria’s Mohs hardness is ~6—softer than zirconia but harder than the glass. This “Goldilocks” zone is perfect: hard enough to remove material efficiently, but soft enough to break down under polishing pressure rather than digging into the glass and causing scratches.

- Particle Shape & Morphology: Spherical or rounded cubic particles are ideal. Angular, fractured particles act like tiny knives, increasing scratch risk. High-quality powder is engineered for consistent, benign particle shape.

- The Deal-Breaker: Freedom from Hard Agglomerates. This is the single most critical quality control point. During powder manufacturing, primary nanoparticles can fuse into hard, sintered agglomerates. These agglomerates behave like much larger, uncontrollably hard particles and are guaranteed to cause microscratches or “cicatrix” defects. A reliable supplier uses specialized calcination and milling processes to ensure a de-agglomerated, free-flowing powder.

- Ionic & Metallic Impurity Control: For sensitive applications, trace metals (Fe, Cu, etc.) can cause staining or act as catalysts for surface reactions. Low ionic impurity levels are a mark of advanced processing.

Conclusion: More Than a Powder, A Process Enabler

The shift from smartphone cameras with six lenses to AR glasses requiring waveguide precision isn’t just a change in scale—it’s an exponential tightening of tolerances. In this environment, the polishing consumable is no longer a commodity; it’s a process-defining element.

Precision ceria powder, with its unique chemical-mechanical action, is the only material that consistently meets the dual mandate of high removal rate and atomic-level surface integrity. Choosing a supplier that masters powder morphology, agglomerate control, and purity isn’t just about buying a better powder; it’s about investing in higher yields, fewer reworks, and optics that perform to their theoretical limits.

Ready to see how the right ceria powder can transform your polishing results?

Contact us to receive our practical selection guide and a sample matched to your specific glass type and polishing stage. Let our materials engineers help you eliminate surface defects and achieve the finish your optics demand.