Ytterbium oxide, represented by the chemical formula Yb2O3, is a versatile material valued for its exceptional properties in various industrial and research applications. Its significance lies not only in its inherent qualities but also in the specific customized purity standards demanded by different industries. In this article, we will explore how customized purity standards of Yb2O3 are required in diverse applications, emphasizing the critical role of purity in its performance.

Different industries and applications demand Yb2O3 with varying purity levels to ensure optimal performance. These tailored purity standards are critical for harnessing the material's full potential. Here's a closer look at some key industries and their specific purity requirements:

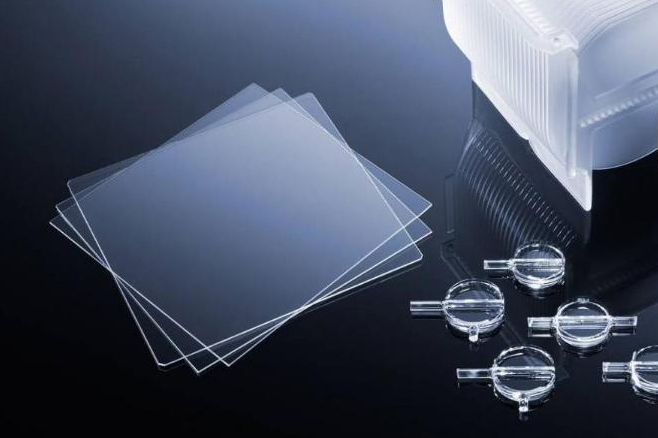

In the field of optics, Yb2O3 is utilized in lenses, optical coatings, and laser gain media. To achieve outstanding light transmission and minimal optical losses, the purity standards for Yb2O3 in this industry are exceptionally high, often requiring 99.99% or greater purity. Any impurities can compromise its optical properties, making purity a top priority.

Yb2O3 serves as a catalyst support in various chemical reactions. The purity standards here are primarily dictated by the catalytic process's sensitivity to impurities. While high purity, such as 99.9%, is usually sufficient, achieving purity levels of 99.99% or higher may be necessary for specific catalytic applications to prevent unintended chemical interactions.

In the electronics industry, Yb2O3 contributes to the production of superconductors and high-k dielectric materials. The purity standards required are stringent, often at 99.99% or greater. High purity is vital to maintain the electronic properties needed in electronic devices and semiconductor manufacturing.

Solid-state lasers rely on Yb2O3 for its exceptional light amplification properties. Achieving high purity is crucial to enhance its performance as a laser gain media. Purity levels commonly exceed 99.99% to ensure predictable and consistent laser output.

Yb2O3 plays a key role in the creation of phosphors for lighting and display technologies. Purity standards are tailored to achieve intense and efficient light emission. Purity levels ranging from 99.9% to 99.99% are often required to meet the specific requirements of this industry.

The varied applications of Yb2O3 in different industries necessitate tailored purity standards to unlock its full potential. These purity standards, often ranging from 99.9% to 99.99% or higher, ensure that Yb2O3 performs optimally in optics, catalysis, electronics, laser technology, and lighting technologies. Understanding the critical role of purity in different applications is essential for harnessing the unique properties of Yb2O3 effectively.

For more information about high purity ytterbium oxide materials, please visit https://www.stanfordmaterials.com/.

Eric Loewen

Eric Loewen graduated from the University of Illinois studying applied chemistry. His educational background gives him a broad base from which to approach many topics. He has been working with topics about advanced materials for over 5 years at Stanford Materials Corporation (SMC). His main purpose in writing these articles is to provide a free, yet quality resource for readers. He welcomes feedback on typos, errors, or differences in opinion that readers come across.

Inquiry List

Inquiry List