As semiconductor devices shrink to the 3nm node and beyond, and as demands for sapphire-based substrates grow, the margin for error in Chemical Mechanical Planarization (CMP) vanishes. This article examines why high-purity, nano-sized ceria (CeO₂) slurries are becoming indispensable for achieving the required atomic-level surface perfection. We break down the unique chemical-mechanical synergy of ceria, show the critical slurry specifications that dictate performance, and explain how advanced material synthesis directly translates to higher yield and lower cost of ownership in leading-edge manufacturing.

Introduction: The Flattening Imperative in Advanced Manufacturing

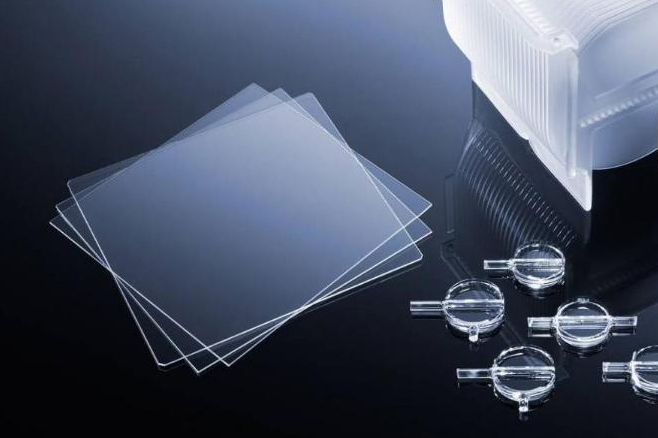

The relentless drive for miniaturization and performance in semiconductors and optoelectronics has made surface flatness a non-negotiable specification. In 3D NAND flash memory, with its towering stacks of layers, and in advanced logic chips, any nanometer-scale topography can cause lithography defocus and device failure. Similarly, for LEDs and RF devices built on sapphire substrates, sub-nanometer surface roughness is critical for epitaxial layer quality. Chemical Mechanical Planarization (CMP) is the only process capable of achieving global, atomic-level planarity across an entire wafer. The heart of this process is not the polisher itself, but the slurry—a complex colloidal suspension whose abrasive particles determine the outcome. Among abrasives, nano-ceria (CeO₂) has emerged as a superior solution for silicon oxide and sapphire removal, outperforming traditional silica and alumina through a fundamentally different mechanism.

Beyond Abrasion: The Chemical-Mechanical Synergy of Ceria

Traditional CMP abrasives like silica (SiO₂) and alumina (Al₂O₃) primarily function through mechanical wear—a grinding action that can introduce surface and sub-surface damage. Nano-ceria operates on a more sophisticated principle of site-specific chemical reactivity followed by gentle mechanical removal.

- Selective Chemical Bonding: In SiO₂ CMP, CeO₂ nanoparticles do not indiscriminately attack the surface. The cerium ions (Ce⁴⁺) on the particle surface have a high affinity for the oxygen atoms in the silicon dioxide (SiO₂) network. This leads to the formation of a transient Ce-O-Si chemical bond at the interface.

- Low-Energy Removal: This chemical bonding weakens the underlying Si-O bonds in the silica layer. The mechanical action of the pad and particle sliding then easily shears off this reacted layer. This process is inherently more selective and less damaging than pure fracture-based abrasion.

- The Result: A surface that is not just flat, but also has minimal crystal lattice damage, lower roughness, and fewer defects—all of which are paramount for subsequent processing steps and ultimate device performance.

Decoding Slurry Performance: The Three Pillars of Specification

Not all ceria slurries are created equal. Performance and defectivity are dictated by precise control over physical and chemical properties.

| Key Performance Indicator |

Target Specification & Control |

Impact on CMP Process |

| Particle Size Distribution & Morphology |

Narrow distribution (e.g., D50 ~ 80-150nm); Spherical shape preferred. |

Uniform removal rate and surface finish. Agglomerates or large tails in the distribution cause microscratches. Spherical particles reduce mechanical damage compared to angular ones. |

| Zeta Potential & Dispersion Stability |

High absolute zeta potential (ζ > ±30 mV) at process pH. |

Prevents particle settling and agglomeration in the slurry supply system. Instability leads to concentration gradients, rate variation, and catastrophic defect events (clogs, scratches). |

| Metallic & Ionic Impurities |

Ultra-low levels (≤ ppb for critical metals like Fe, Cu, Al, Na, K). |

Prevents mobile ion contamination in semiconductors, which can degrade gate oxide integrity and cause device failure. Essential for high-k/metal gate and memory applications. |

The SMC Advantage: From Powder Synthesis to Performance Assurance

At Stanford Materials Corporation (SMC), we approach ceria slurry not as a commodity chemical, but as a precision-engineered consumable. Our vertically integrated control over the entire production chain ensures unmatched consistency and performance.

- High-Purity Nano-Powder Synthesis: We utilize controlled precipitation and thermal processes to synthesize high-purity (>99.99%) CeO₂ nanoparticles. Our proprietary methods allow precise command over primary particle size, crystallinity, and, most importantly, surface chemistry, which is the foundation of the chemical-mechanical effect.

- Advanced Dispersion Technology: We employ surface modification and state-of-the-art dispersion techniques to de-agglomerate primary particles and stabilize them in suspension. This results in a slurry with exceptional shelf life and in-tool stability, eliminating a major source of process variation.

- Formulation Expertise: Our slurries are optimized with specific chelating agents, oxidizers, and pH regulators tailored for different applications (e.g., ILD STI polishing vs. sapphire substrate polishing). We provide not just a slurry, but a complete process window recommendation.

Conclusion: Partnering for Flawless Surfaces

The transition to advanced nodes and compound semiconductors has made CMP one of the most critical—and challenging—process steps. The choice of slurry abrasive is a fundamental decision that cascades through yield, device performance, and factory economics. Ceria-based slurries, with their unique chemical-mechanical action, offer a clear path to the atomic-level planarity these technologies demand.

However, realizing this potential requires a supplier with deep materials science expertise and meticulous production control. Stanford Materials Corporation (SMC) partners with leading manufacturers to provide ceria slurry solutions that deliver predictable removal rates, exceptionally low defect densities, and the contamination control required for cutting-edge fabrication.

Ready to optimize your CMP process for defect-free planarization?

Contact an SMC application engineer today to discuss your specific material (SiO₂, SiN, Sapphire) and process requirements. We will provide a tailored sample and a comprehensive evaluation protocol to validate performance in your application.