Erbium oxide stands out as a unique compound that has slowly found its way into many practical applications. With its strong optical and electronic properties, this rare-earth material has built a reputation in industries such as telecommunications, medicine, display manufacturing, and even scientific research. The steady rise in technology needs has led many professionals to use erbium oxide in everyday devices and systems. In the following sections, we look at the five essential uses of erbium oxide and the impact it has on modern technology.

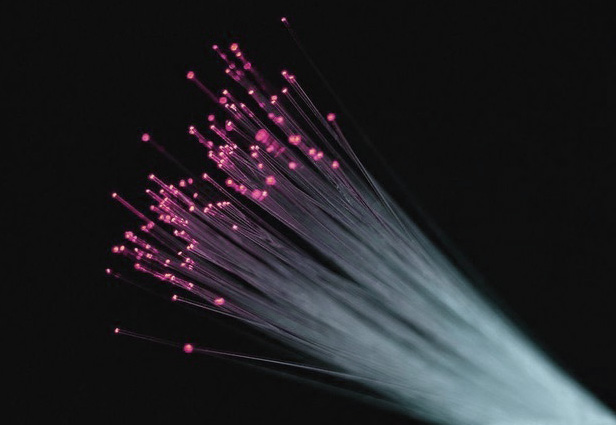

Optical fiber amplifiers are a crucial part of modern communications. These devices help boost the light signals that travel along fiber cables. In practice, erbium is added to fiber amplifiers to enhance signal strength and clarity. This process ensures that data sent over long distances keeps its quality high. Many telecommunications companies use these amplifiers because they reduce delays and improve the overall speed of data transfer. For example, with the ongoing growth in cloud services and the 5G network rollout, there is a rising need for better signal transmission. Actual performance tests show improvements such as lower latency and higher bandwidth when erbium oxide is used correctly. Simple adjustments in the manufacturing process, using methods like chemical vapor deposition, ensure that the distribution of erbium remains perfectly even in the fiber.

The role of erbium oxide in laser technologies is both practical and varied. In the medical arena, lasers that include erbium oxide are used for precise skin treatments, dental procedures, and eye surgeries. The lasers allow for very small amounts of tissue to be removed without causing much heat damage, which leads to quicker patient recovery times and fewer side effects.

In industrial applications, erbium-based lasers are valued for their ability to cut or weld hard materials such as metals and ceramics with a high degree of accuracy. Factories that use these lasers report improved productivity and fewer errors in the manufacturing process. The stability of erbium oxide means that these laser systems operate smoothly, even under constant use.

Another practical use of erbium oxide appears in display and imaging panels. In many modern screens and projectors, the inclusion of erbium oxide helps bring out sharper colors and greater brightness. For instance, televisions and computer monitors benefit from its ability to refine image clarity. This enhancement means that pictures and videos look better and more lifelike. Medical imaging machines also use components enriched with erbium oxide. These devices produce clearer images that help doctors see detailed internal structures, leading to more accurate diagnoses. Numerous consumer tests have shown that screens with erbium oxide-enhanced phosphors exhibit superior clarity compared to standard models.

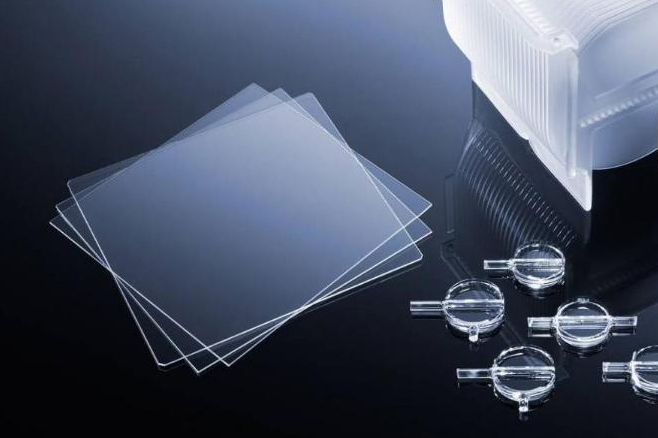

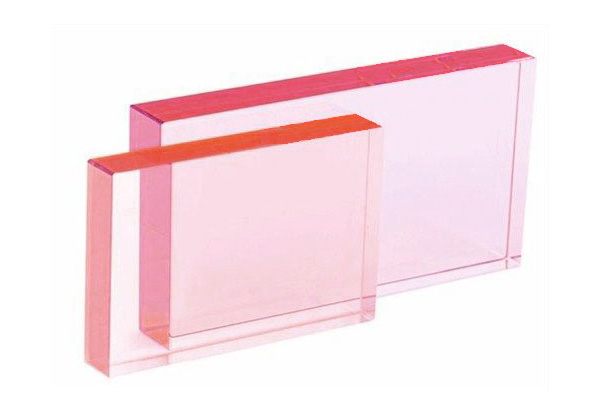

Laser glass and other optical components are essential for high-precision work in many advanced fields. By mixing erbium oxide into specialty glasses or ceramics, manufacturers create materials with excellent clarity and durability. Such materials are vital for research equipment, as well as for defense and aerospace applications. Laboratory tests confirm that these newly formed glasses maintain their form under high temperature and intense light conditions. Instruments that rely on these components perform steadily even in difficult environments. The control over light provided by erbium oxide means that these optical elements provide very precise results, contributing to more reliable measurements in scientific research.

In recent years, attention has also turned to the use of erbium oxide in quantum and photonic applications. While still early in development, initial laboratory work shows that erbium oxide has potential for controlling light at very specific wavelengths. This ability is seen as promising for future quantum memory devices or next-generation computing components. Though these applications are not yet common in everyday devices, tests with erbium oxide have shown stable performance, indicating that it might soon be key in building advanced quantum processors. Such research hints at a time when quantum computing could benefit greatly from the unique properties of erbium oxide.

Integrating erbium oxide into products calls for careful handling and precise techniques. The material is often mixed with other components or embedded in various host matrices. Common manufacturing methods include sol-gel techniques, sputtering, and chemical vapor deposition. Each of these methods helps ensure that the erbium remains evenly spread throughout the product. It is important that companies follow strict regulatory guidelines to maintain purity and ensure the material is safe to use. Handling procedures are mindful not only of product performance but also of environmental and worker safety. Regular checks and adherence to international standards help maintain a high level of consistency and legal compliance.

The outlook for erbium oxide in modern technology remains very positive. Its use in enhancing communication networks, improving laser procedures, refining image quality, and contributing to advanced research demonstrates its versatility. Many industries notice that products perform better when erbium oxide is part of the design. As manufacturers invest in research and sustainable sourcing practices, the benefits of erbium oxide will continue to spread. For anyone in the business of sourcing quality materials, it is well worth considering a supplier known for reliability and performance.

For trusted and consistent erbium oxide, reach out to Stanford Materials Corporation (SMC).

Eric Loewen

Eric Loewen graduated from the University of Illinois studying applied chemistry. His educational background gives him a broad base from which to approach many topics. He has been working with topics about advanced materials for over 5 years at Stanford Materials Corporation (SMC). His main purpose in writing these articles is to provide a free, yet quality resource for readers. He welcomes feedback on typos, errors, or differences in opinion that readers come across.