Cerium oxide (CeO2), a versatile and influential catalyst, plays a pivotal role in automotive exhaust systems, significantly contributing to the reduction of harmful emissions. In recent years, the automotive industry has increasingly turned to CeO2 for its unique properties, aiming to align with stringent environmental standards. This article explores the multifaceted role of cerium oxide in automotive catalysts, shedding light on its unparalleled advantages and diverse applications across various vehicular systems.

Cerium oxide, commonly referred to as ceria (CeO2), stands out as a catalyst due to its exceptional ability to initiate and facilitate chemical reactions within automotive exhaust systems. As we delve deeper into its chemical characteristics, we uncover the intricate mechanisms that make the material a standout component in the pursuit of cleaner and more environmentally friendly transportation. The exploration of its physical and chemical properties provides a foundation for comprehending its pivotal role in the complex world of automotive catalysts.

Oxygen Storage Capacity (OSC):

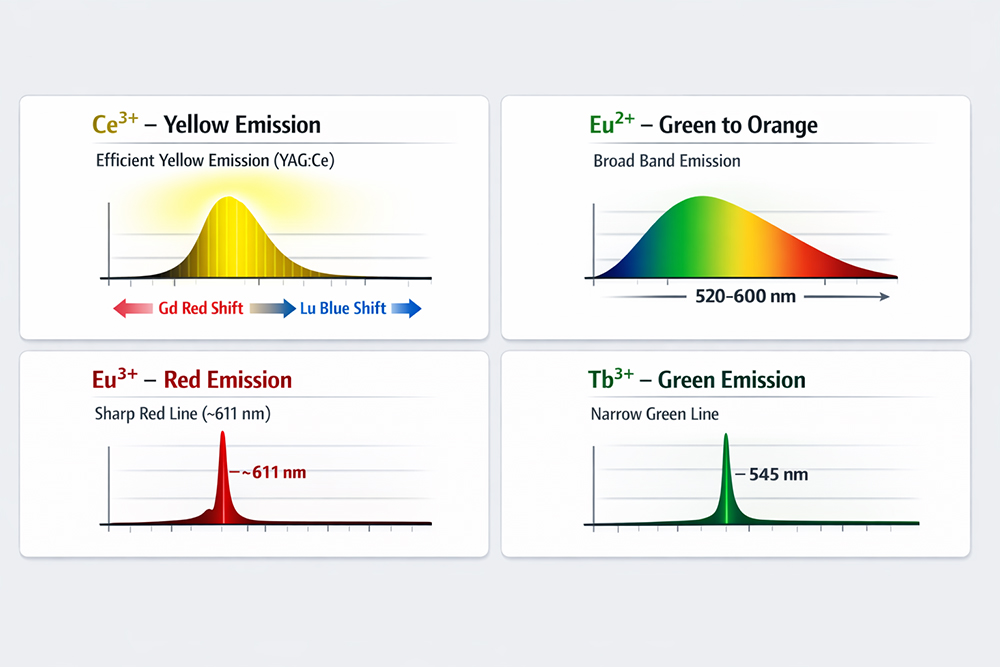

At the heart of CeO2's effectiveness lies its remarkable oxygen storage capacity (OSC). This unique feature allows cerium oxide to serve as a dynamic reservoir of oxygen, crucial for the optimization of combustion conditions within the engine. As we dissect the intricacies of OSC, we gain insight into how this property enables cerium oxide to play a central role in the reduction of harmful emissions.

Enhanced Catalytic Activity:

The catalytic prowess of cerium oxide extends beyond its OSC capabilities. Its inherent ability to enhance catalytic activity stands as a linchpin in the conversion of detrimental gases, such as nitrogen oxides (NOx) and carbon monoxide (CO), into less harmful substances. A detailed examination of the catalytic mechanisms at play provides a comprehensive understanding of how cerium oxide contributes to meeting and exceeding stringent emission standards.

Resistance to Sintering:

One of the enduring challenges faced by automotive catalysts is the phenomenon of sintering, where catalyst particles agglomerate and compromise their effectiveness over time. Cerium oxide, however, exhibits an inherent resistance to sintering, thereby ensuring the longevity and durability of automotive catalysts. By delving into the science behind this resistance, we uncover the factors that make ceria a reliable and robust choice for sustainable catalytic solutions.

Three-Way Catalysts (TWC):

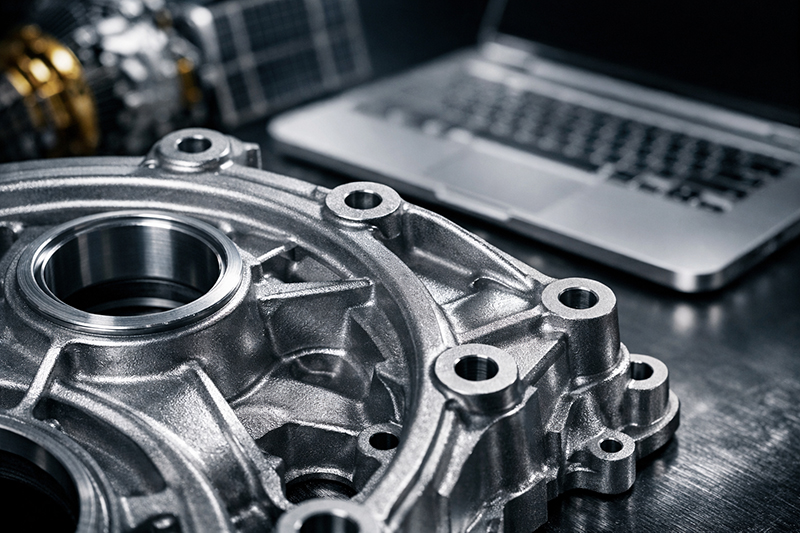

The utilization of cerium oxide in three-way catalysts (TWC) is a cornerstone of emission control in gasoline-powered vehicles. An in-depth exploration of the intricate chemistry involved in TWCs reveals the nuanced ways in which cerium oxide facilitates the simultaneous reduction of nitrogen oxides (NOx), carbon monoxide (CO), and unburned hydrocarbons, thereby ensuring compliance with stringent emission regulations.

Diesel Oxidation Catalysts (DOC):

As we shift our focus to diesel engines, the application of cerium oxide in Diesel Oxidation Catalysts (DOC) becomes apparent. These catalysts, essential for reducing harmful diesel exhaust pollutants, exemplify the versatility of cerium oxide across different engine types. A detailed examination of the catalytic processes within DOCs provides a comprehensive understanding of how cerium oxide contributes to the conversion of particulate matter and hydrocarbons into less harmful substances, aligning with the overarching goal of minimizing the environmental impact of diesel-powered vehicles.

Selective Catalytic Reduction (SCR):

The implementation of cerium oxide in Selective Catalytic Reduction (SCR) systems for diesel engines represents a technological breakthrough in emission reduction. SCR systems, relying on the catalytic prowess of cerium oxide, target nitrogen oxide (NOx) emissions, converting them into nitrogen, water, and carbon dioxide. A thorough exploration of the chemical reactions and mechanisms involved in SCR systems underscores the integral role played by cerium oxide in the quest for cleaner diesel exhaust.

In conclusion, the utilization of cerium oxide in automotive catalysts stands as a beacon of progress in the ongoing pursuit of cleaner and more sustainable transportation. As we reflect on the advantages outlined – from its high oxygen storage capacity and enhanced catalytic activity to its resistance to sintering – it becomes evident that cerium oxide is not merely a catalyst but a catalyst for positive change in the automotive industry. Its diverse applications in three-way catalysts (TWC), Diesel Oxidation Catalysts (DOC), and Selective Catalytic Reduction (SCR) systems underscore its adaptability and effectiveness across various vehicular systems.

As we strive for reduced emissions and a greener automotive landscape, cerium oxide emerges as a testament to the pivotal role that catalysts play in shaping the future of automotive technology. By fostering a deeper understanding of cerium oxide's advantages and applications, this article aims to contribute to the broader discourse on sustainable transportation and inspire continued innovation in catalytic solutions.

Eric Loewen

Eric Loewen graduated from the University of Illinois studying applied chemistry. His educational background gives him a broad base from which to approach many topics. He has been working with topics about advanced materials for over 5 years at Stanford Materials Corporation (SMC). His main purpose in writing these articles is to provide a free, yet quality resource for readers. He welcomes feedback on typos, errors, or differences in opinion that readers come across.

Inquiry List

Inquiry List