Shape Memory Alloys demonstrate a unique ability to recover their initial shape after deformation through a reversible thermo-elastic phase transformation, it allows Shape Memory Alloys to recover large strains, either spontaneously (pseudo elasticity) or through an increase in temperature (Shape Memory Effect). Among the commercially available Shape Memory Alloys, nickel-titanium (Ni-Ti and Ni–Ti-based) ones are outstanding due to their excellent performance and reliability, in addition to strain recovery, Ni-Ti is attractive for several medical applications due to its biocompatibility, corrosion resistance, and fatigue behavior.

The near-atomic ratio of Ti-Ni alloy was the first material to be used as a shape-memory alloy. Due to its excellent shape memory function, good heat and corrosion resistance, high strength, unique thermal and fatigue resistance, high biocompatibility, and high damping characteristics, it is widely used in many fields.

Ti-Ni shape memory alloy's Phase Transition Temperature is very sensitive to its composition, with each additional 0.1% Ni causing the Phase Transition Temperature to drop 10°C. Adding a third element will also significantly influence the Ti-Ni alloy's Phase Transition Temperature.

Nitinol Memory Alloy Application

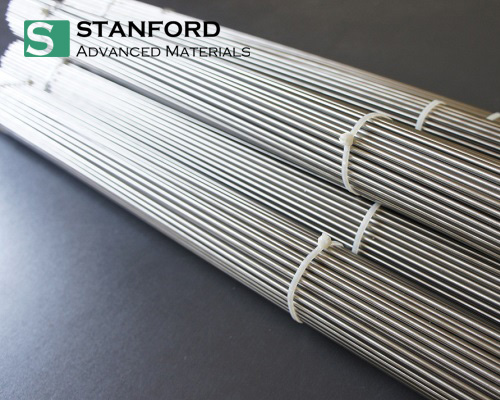

Ti-Ni shape-memory alloy wire can be used in cell phone antennas, children's toys, experimental materials, eyeglasses components, and medical equipment such as surgical stitching wire, birth control loop,s and high-quality memory alloy wire of other areas.

Nitinol Memory Alloy Specification

| Product |

Size |

Composition |

Application |

| Rod & Wire |

0.1mm min Dia. |

Ni: 54.5-57%, Ti: Balance |

Spring, Finishing rod, Medical |

| Plate & Sheet & Strip (Cold rolled) |

0.05mm min T x 270mm max W x L |

Ni: 54.5-57%, Ti: Balance |

Spring, Medical Equipment and Implant Part |

| Tube & Capillary |

0.8mm OD Min x 0.15mm x L |

Ni: 54.5-57%, Ti: Balance |

Medical Equipment and Implant Part |

Nitinol Memory Alloy Type

| Type |

Description |

| Two way-Shape Memory |

Alloy that restore high-temperature phase shape when heated, and restore cooling temperature phase shape when cooled |

| One way-Shape Memory |

Alloy deform at lower temperature, restore the shape before deformation when heated. It only shows shape memory phenomenon when heating |

Nitinol Memory Alloy Glossary

Shape Memory Effect: "Shape Memory" describes the effect of restoring the original shape of a plastically deformed sample by heating it.

Superelastic Effect: An elastic (reversible) response to an applied temperature, caused by a phase transformation between the austenitic and martensitic phases of a crystal.

MS: The starting temperature of SMA transform from austenite to martensite

MF: The ending temperature of SMA transform from austenite to martensite

AS: The starting temperature of SMA transform from martensite to austenite

AF: The ending temperature of SMA transform from martensite to austenite

Memory Alloy Products

Memory Alloy Strip

Memory Alloy Spring

Memory Alloy Sheet

Memory Alloy Capillary

Memory Alloy Wire

Memory Alloy Wire Illustrate