Praseodymium Planar Target Description

Stanford Materials Corporation (SMC) provides high-purity Praseodymium Planar Targets, known for their excellent oxidation resistance, thermal stability, and unique magnetic and optical properties. Praseodymium is a rare-earth metal with a bright silvery appearance and a relatively high melting point of 931°C, making it ideal for thin-film deposition applications that require stability in extreme conditions. Due to its high reactivity with oxygen, it forms a protective oxide layer that enhances its corrosion resistance and environmental durability, ensuring the longevity and reliability of deposited films.

A key advantage of praseodymium is its ability to enhance the magnetic, electrical, and optical performance of thin-film coatings, making it essential in various advanced material applications. With its fine grain structure and high purity, praseodymium ensures uniform film deposition with minimal defects, enhancing the overall quality and efficiency of the sputtering process. SMC offers praseodymium planar targets in different purities and customized dimensions to suit specific industry needs. Thanks to advanced manufacturing techniques and rigorous quality control, SMC guarantees consistent performance, making their praseodymium sputtering targets an excellent choice for industries demanding high-precision thin films and coatings.

Praseodymium Planar Target Specification

Properties

- Purity: 99.9%

- Theoretical Density: 6.77 g/cm³

- Melting Point: 935 °C

- Boiling Point: 3520°C

- Product Size: Customized

Note: The above product data is based on theoretical information. For specific requirements and inquiries, please contact us.

Praseodymium Planar Target Applications

Praseodymium planar sputtering targets are extensively used in thin-film deposition for various high-tech applications, owing to their unique magnetic, optical, and electrical properties. In the electronics and semiconductor sectors, praseodymium is used in dielectric and insulating films to enhance microelectronic device performance. Its excellent optical features make it valuable for optical coatings, including high-performance lenses, filters, and laser systems.

Praseodymium is also essential in magnetic storage technologies, contributing to the development of advanced data storage solutions. In the energy sector, it is used in specialized thin films for fuel cells and catalytic converters, enhancing efficiency and durability. Additionally, praseodymium-doped materials find applications in ceramic coatings, protective layers, and functional thin films for aerospace and industrial uses. With its outstanding stability and film-forming properties, praseodymium planar targets play a vital role in cutting-edge research and advanced material development.

Praseodymium Planar Target Packaging

Our products are packaged in customized cartons of various sizes based on material dimensions. Smaller items are securely packed in PP boxes, while larger items are placed in custom wooden crates. We ensure strict adherence to packaging requirements and use appropriate cushioning materials to ensure optimal protection during shipping.

Packaging: Carton, Wooden Box, or Customized.

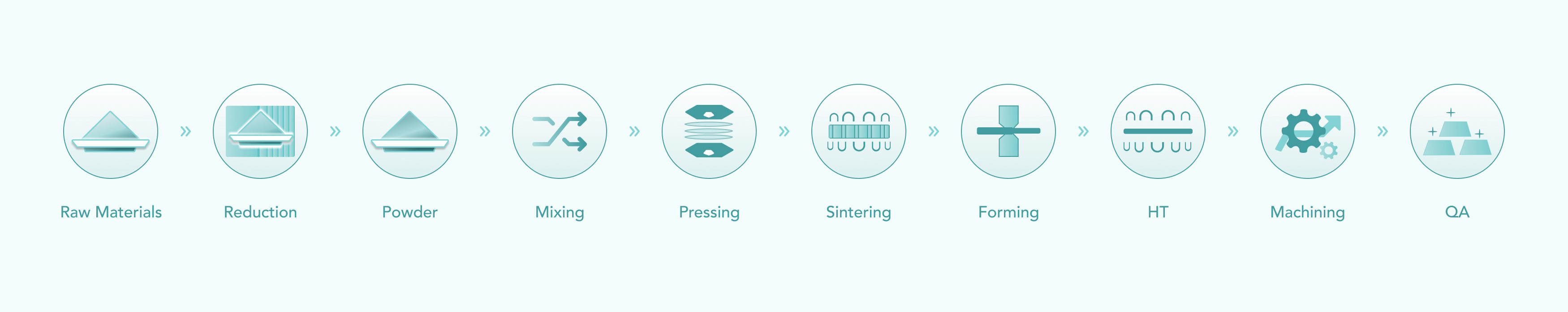

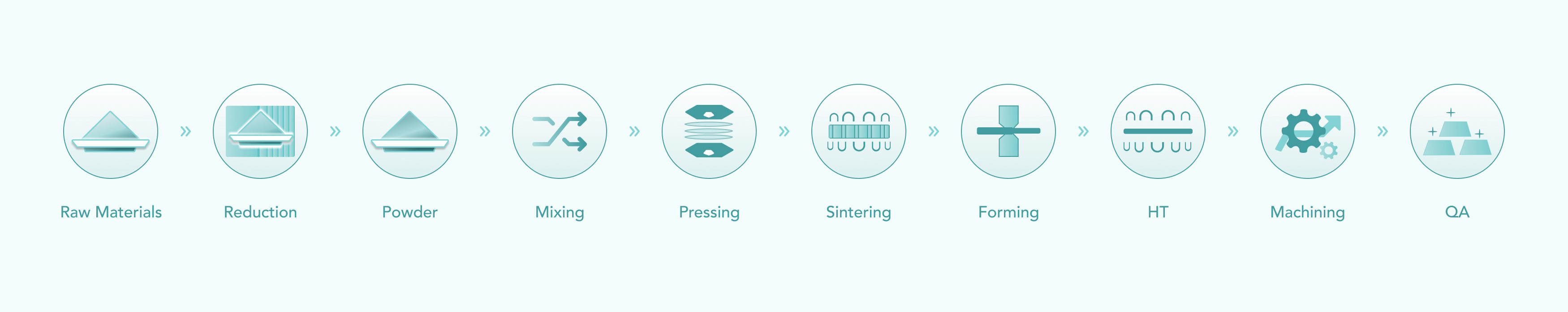

Manufacturing Process

-

Testing Method

- Chemical Composition Analysis: Verified using techniques like GDMS or XRF to ensure purity compliance.

- Mechanical Properties Testing: Includes tests for tensile strength, yield strength, and elongation to assess material performance.

- Dimensional Inspection: Ensures thickness, width, and length meet specified tolerances.

- Surface Quality Inspection: Visual and ultrasonic checks for defects like scratches, cracks, or inclusions.

- Hardness Testing: Assesses material hardness to confirm uniformity and mechanical reliability.

Praseodymium Planar Target FAQs

Q1: What are the primary advantages of praseodymium in thin-film coatings?

A1: Praseodymium offers excellent oxidation resistance, thermal stability, and unique magnetic and optical properties, making it perfect for advanced material applications.

Q2: What are the common applications of praseodymium sputtering targets?

A2: These targets are widely used in electronics, semiconductor coatings, optical films, magnetic storage devices, fuel cells, and high-performance ceramic coatings.

Q3: Can the size and shape of praseodymium planar targets be customized?

A3: Yes, we provide customized dimensions, shapes, and bonding options to suit different sputtering system requirements.

Performance Comparison Table with Competitive Products

Praseodymium Rotary Target vs. Praseodymium Planar Target

| Feature |

Praseodymium Rotary Target |

Praseodymium Planar Target |

| Material Utilization |

Up to 80-90% |

Around 30-40% |

| Service Life |

Longer, reducing replacement frequency |

Shorter, requiring more frequent replacement |

| Coating Uniformity |

More uniform, ideal for large-area coatings |

May have thickness variations |

| Production Cost |

Higher initial cost but more economical in the long term |

Lower initial cost but requires more frequent changes |

| Applications |

Large-area coatings (TFT-LCD, solar cells, optical coatings) |

Small-area coatings (semiconductors, precision electronics) |

| Sputtering Stability |

More stable, reducing material loss |

Potentially less stable due to uneven erosion |

| Compatible Equipment |

Requires rotary sputtering systems |

Compatible with traditional planar sputtering systems |

Related Information

1. Raw Materials - Praseodymium

Praseodymium (Pr) is a rare-earth metal with the atomic number 59 and an atomic weight of 140.91. It is a soft, silvery metal that reacts readily with oxygen, forming a protective oxide layer that helps prevent further corrosion. With a melting point of 931°C (1,708°F), praseodymium exhibits excellent magnetic, electrical, and optical properties.

Praseodymium is found in rare-earth minerals like monazite and bastnäsite, where it is extracted and refined for industrial use. Due to its paramagnetic nature and ability to form stable compounds, praseodymium is used in magnets, optical coatings, ceramics, and high-performance alloys. It is also a key component in praseodymium-doped glass and lasers, which find applications in scientific and industrial fields. Thanks to its unique combination of thermal stability, corrosion resistance, and functional properties, praseodymium plays an essential role in advanced material technologies.