Lanthanum aluminum oxide (LaAlO₃) is a perovskite-structured oxide material known for its stable crystal lattice, high dielectric constant, and chemical compatibility with a wide range of functional materials. Its optical and electronic characteristics make it a reliable choice for advanced ceramics and oxide-based thin film devices. With growing demand for transparent ceramics and complex oxide electronics, LaAlO₃ plays a vital role in applications ranging from laser optics to next-generation transistors.

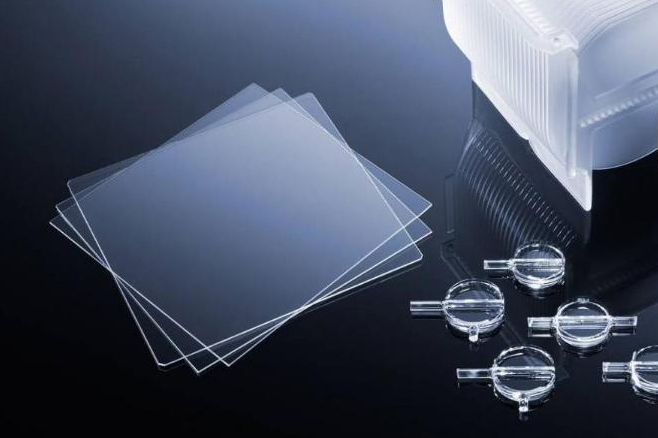

In its sintered ceramic form, lanthanum aluminate exhibits:

High transparency across UV, visible, and near-infrared ranges. This optical clarity makes it suitable for advanced windows and protective layers in optoelectronic systems.

Excellent mechanical strength, offering high hardness and resistance to mechanical shock—important for applications requiring durability under impact or abrasion.

Thermal and chemical stability, enabling long-term performance in high-temperature or corrosive environments without degradation or clouding.

These features give LaAlO₃ a performance edge in environments where both optical performance and structural reliability are required.

LaAlO₃-based transparent ceramics have been evaluated for:

Optical windows in high-energy laser systems, IR sensors, and environmental monitoring instruments. The material’s transmission and thermal stability are well-suited to these needs.

Transparent armor and protective optics, where mechanical integrity and optical clarity must coexist—such as in aerospace domes or armored glass.

Optical component substrates, offering low birefringence and good polishability for high-precision devices.

Processing typically involves solid-state sintering or hot-pressing, with tight control over grain size and porosity to ensure transparency and strength. Doping or co-sintering with other oxides is sometimes used to optimize mechanical or optical behavior.

LaAlO₃ also plays a significant role in thin film technologies, particularly as a substrate or dielectric layer:

High-k dielectric layers in advanced transistors (e.g., MOSFETs), where its high dielectric constant enables device miniaturization while controlling leakage currents.

Perovskite heterostructures, where LaAlO₃ forms interfaces with materials like SrTiO₃ to create two-dimensional electron gases (2DEG)—a platform for novel electronic and quantum devices.

Optical coatings and sensors, using LaAlO₃ thin films to tune refractive index, improve durability, or serve as functional buffer layers in complex stacks.

These films are commonly deposited by pulsed laser deposition (PLD), molecular beam epitaxy (MBE), or sputtering, depending on application requirements.

Lanthanum aluminate offers a rare combination of optical clarity, thermal robustness, and structural compatibility. Whether used as a bulk ceramic or a precision thin film, its properties support demanding optical and electronic functions.

For those developing infrared optics, laser systems, or oxide-electronic devices, LaAlO₃ is a material worth close consideration. At Stanford Materials Corporation, we supply lanthanum aluminate in a range of forms—from high-purity powders to custom-machined ceramics and film deposition targets—backed by technical support and batch consistency.

Explore our LaAlO₃ offerings or contact us directly for material guidance tailored to your specific needs.

Eric Loewen

Eric Loewen graduated from the University of Illinois studying applied chemistry. His educational background gives him a broad base from which to approach many topics. He has been working with topics about advanced materials for over 5 years at Stanford Materials Corporation (SMC). His main purpose in writing these articles is to provide a free, yet quality resource for readers. He welcomes feedback on typos, errors, or differences in opinion that readers come across.

Inquiry List

Inquiry List