Catalyst support materials play a critical role in modern heterogeneous catalysis. They not only anchor active components but also influence reaction pathways, durability, and overall catalytic efficiency. Among various supports, cerium oxide (CeO₂) has gained increasing attention due to its unique redox properties, thermal stability, and compatibility with a wide range of reactions.

CeO₂ is known for its ability to store and release oxygen easily, making it especially valuable in oxidation–reduction reactions. In recent years, the need for more efficient, stable, and recyclable catalysts has pushed researchers to explore advanced support materials that do more than simply host the active phase. CeO₂ meets this demand with its dual functionality: structural support and chemical enhancement.

This article outlines the key properties of cerium oxide, discusses its advantages as a support material, and highlights its applications in real-world catalytic systems.

Cerium oxide, often referred to as ceria, is a rare earth oxide with a fluorite-type crystal structure. Its basic chemical form is CeO2, though it can exist in mixed valence states (Ce³⁺ and Ce⁴⁺) due to the presence of oxygen vacancies. This ability to switch oxidation states is what enables its notable oxygen storage capacity (OSC).

The material’s oxygen vacancies play a major role in catalytic activity. These defects allow CeO₂ to rapidly take in or release oxygen during redox reactions. The extent of this behavior is often influenced by factors like particle size, morphology, and specific surface area. Nanoscale ceria, for instance, shows much higher OSC compared to its bulk counterpart, mainly due to the greater number of active sites on the surface.

One of the strongest arguments for using cerium oxide as a support is its oxygen mobility. Unlike inert supports such as alumina or silica, ceria can actively participate in redox processes. This becomes particularly useful in oxidation reactions where the regeneration of the active species is crucial.

Ceria also interacts favorably with noble metals like Pt, Pd, and Rh. These interactions often result in stronger metal dispersion and enhanced stability. Additionally, CeO₂ can help prevent metal sintering at high temperatures, maintaining catalytic performance over longer cycles.

Thermal resistance is another important factor. Ceria remains stable under severe thermal conditions, which is essential for applications like automotive exhaust treatment or chemical reactors operating at elevated temperatures.

Nanostructured ceria—whether in the form of nanorods, nanocubes, or mesoporous structures—further improves catalytic behavior by maximizing surface area and tailoring surface defects. These engineered features enhance not just activity but also selectivity and longevity.

A number of preparation techniques have been developed to obtain cerium oxide with desired structural and surface properties:

Sol-gel method: Offers fine control over particle size and surface area; useful for making homogeneous, porous materials.

Hydrothermal synthesis: Allows formation of well-defined nanostructures such as rods and spheres, often with fewer defects.

Precipitation method: A simple and scalable route; commonly used in industrial production.

Other techniques: These include spray pyrolysis, combustion synthesis, and flame spray methods, which are useful for tailoring surface chemistry and creating high-surface-area powders.

Each method can be fine-tuned depending on the intended catalytic application, whether the priority is stability, reactivity, or compatibility with a particular metal.

To evaluate ceria-based catalysts, several parameters are considered:

Catalytic activity: Measured through reactions like CO oxidation, methane reforming, or VOC removal. CeO₂-supported systems often show lower activation energies and faster reaction rates.

Stability and durability: Tested under long-term reaction cycles or thermal stress. Ceria’s structure holds up well, especially when synthesized with controlled porosity.

Oxygen storage performance: OSC is evaluated by redox cycling experiments. Materials with higher OSC generally exhibit more consistent catalytic output.

Interaction with active metals: Techniques such as TEM, XPS, and H₂-TPR are used to study the dispersion, oxidation states, and binding behavior of supported metals.

These evaluations help determine how cerium oxide supports influence the reaction pathway and catalyst life.

Automotive Catalysts

Ceria is a key component in three-way catalysts used for exhaust gas purification. It helps manage oxygen levels dynamically, enabling simultaneous conversion of NOₓ, CO, and hydrocarbons. Modified CeO₂ supports enhance low-temperature activity and aging resistance.

Industrial Chemical Reactions

In chemical manufacturing, CeO₂-supported catalysts are used in reactions like water-gas shift, oxidative dehydrogenation, and steam reforming. The material’s ability to stabilize active metals at high temperatures is particularly beneficial.

Emerging Energy Technologies

CeO₂ has shown promise in solid oxide fuel cells (SOFCs), photocatalysis, and biomass conversion. Its high redox capacity and stability make it a candidate for sustainable energy applications that demand robust and efficient catalysts.

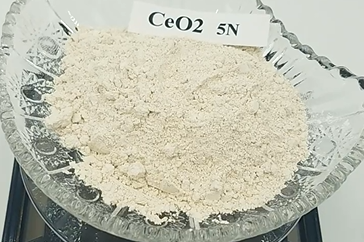

For research labs and industrial developers, material consistency is vital. Stanford Materials Corporation (SMC) supplies high-purity cerium oxide powders tailored for catalyst support applications. Available in various particle sizes, including nano-grade and micron-grade forms, SMC’s ceria products offer:

Purity levels up to 99.999%

Custom particle size distributions

Batch-to-batch consistency

Competitive pricing for both R&D and scale-up needs

Whether you're developing new catalysts or improving existing systems, SMC provides the materials and technical support needed to move forward with confidence.

Eric Loewen

Eric Loewen graduated from the University of Illinois studying applied chemistry. His educational background gives him a broad base from which to approach many topics. He has been working with topics about advanced materials for over 5 years at Stanford Materials Corporation (SMC). His main purpose in writing these articles is to provide a free, yet quality resource for readers. He welcomes feedback on typos, errors, or differences in opinion that readers come across.