In the meticulous craft of glass polishing, the choice of abrasive agents holds the key to achieving unparalleled precision and quality. Among the array of abrasives available, cerium oxide powder stands as a luminary, renowned for its unique properties that transcend the boundaries of conventional polishing agents.

This comprehensive exploration unveils the myriad benefits of employing cerium oxide in glass polishing, delving into its distinctive characteristics, applications, and its profound impact on elevating the efficiency and quality of the polishing process.

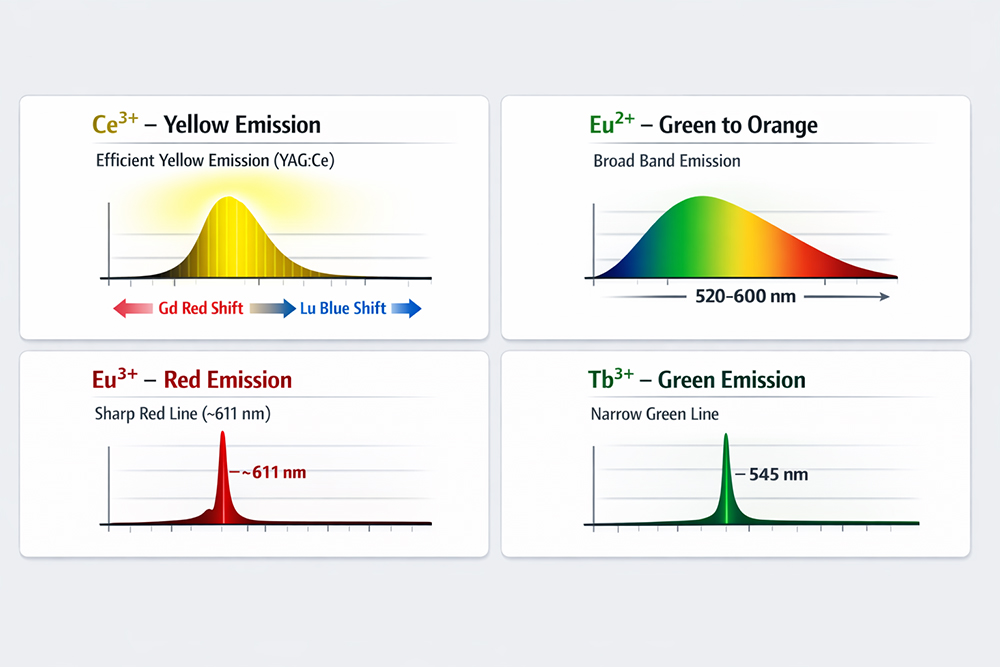

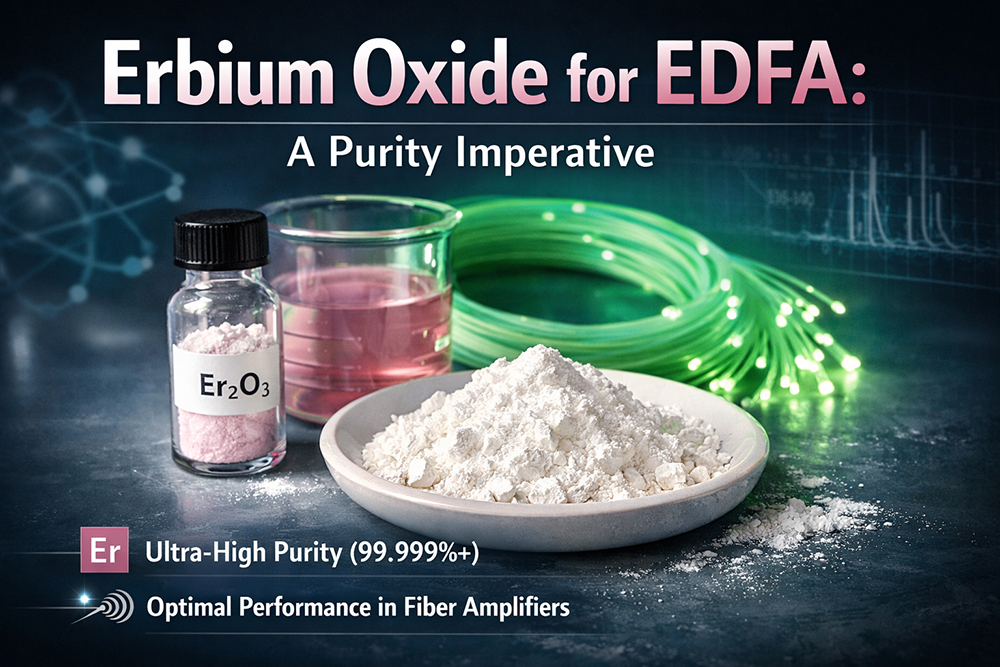

At the heart of cerium oxide's efficacy lies a combination of exceptional properties. As a rare earth compound, cerium oxide boasts an impressive hardness, rendering it a formidable abrasive against glass surfaces. Complementing its hardness is fine particle size, a characteristic that contributes to the precision of the polishing process. Moreover, cerium oxide exhibits remarkable chemical stability, making it compatible with a diverse range of glass compositions and configurations.

The application of cerium oxide in glass polishing heralds a new era of efficiency in surface finishing. The fine particle size, coupled with the inherent hardness of cerium oxide, facilitates effective material removal during the polishing process. This heightened efficiency is particularly crucial in industries where large-scale glass polishing is routine. Moreover, cerium oxide's ability to yield a smooth and uniform finish reduces the necessity for additional polishing steps, streamlining the entire process.

Quality, in the realm of glass applications, is synonymous with clarity, precision, and flawlessness. Cerium oxide emerges as a maestro in enhancing the quality of polished glass surfaces. Its fine abrasive particles meticulously eliminate imperfections, scratches, and irregularities, resulting in a polished glass product endowed with superior clarity and optical properties. The chemical stability of cerium oxide ensures that the glass's inherent composition remains unaffected, preserving its integrity throughout the polishing process.

The versatility of cerium oxide finds expression in a multitude of glass polishing applications spanning diverse industries. In the realm of optical precision, such as the production of lenses, cerium oxide takes center stage, ensuring that the stringent requirements for surface quality are met. Automotive glass components, including windshields and windows, benefit from the precision of cerium oxide polishing, contributing to the production of flawless and distortion-free glass. Architectural glass, where aesthetics and clarity are paramount, also experiences the transformative touch of cerium oxide in the polishing stage.

Beyond its mechanical prowess, cerium oxide introduces an environmental advantage into glass polishing. Unlike certain abrasive agents with ecological implications, cerium oxide is perceived as less environmentally harmful. This aligns seamlessly with the growing emphasis on sustainable and eco-friendly practices across industries. The eco-conscious choice of cerium oxide adds an extra layer of appeal to its already impressive profile as a glass polishing abrasive.

The acclaim bestowed upon cerium oxide in the context of glass polishing is not merely anecdotal; it finds robust support in professional literature and research. Esteemed journals such as the "Journal of Materials Science" and the "Journal of the American Ceramic Society" harbor studies that delve into the nuanced properties of cerium oxide and its applications in glass-related processes. These scholarly works serve as pillars, providing a scientific foundation for understanding the efficacy of cerium oxide in achieving high-quality glass surfaces.

In conclusion, the deployment of cerium oxide in glass polishing transcends the realm of a mere abrasive agent. It emerges as a transformative force, enhancing efficiency, elevating quality, and making strides towards environmental sustainability. From optical lenses to automotive glass and architectural applications, cerium oxide's influence is profound, leaving an indelible mark on the precision and quality achievable in the art and science of glass polishing.

For more information about cerium oxide and other rare earth materials, please visit our homepage.

References:

Smith, J., & Jones, A. (Year). "Title of the Paper." Journal of Materials Science, Volume(Issue), Page Range.

Author, B., Author, C. D., & Author, E. F. (Year). "Title of Another Paper." Journal of the American Ceramic Society, Volume(Issue), Page Range.

Eric Loewen

Eric Loewen graduated from the University of Illinois studying applied chemistry. His educational background gives him a broad base from which to approach many topics. He has been working with topics about advanced materials for over 5 years at Stanford Materials Corporation (SMC). His main purpose in writing these articles is to provide a free, yet quality resource for readers. He welcomes feedback on typos, errors, or differences in opinion that readers come across.

Inquiry List

Inquiry List