Rare earth metal oxides play a significant role in various industries, including the production of glass, ceramics, and semiconductors. One such metal oxide is cerium oxide, also known as ceria. This article discusses the various applications of cerium oxide in polishing, decolorization, and clarification, its properties, practical applications, and environmental challenges.

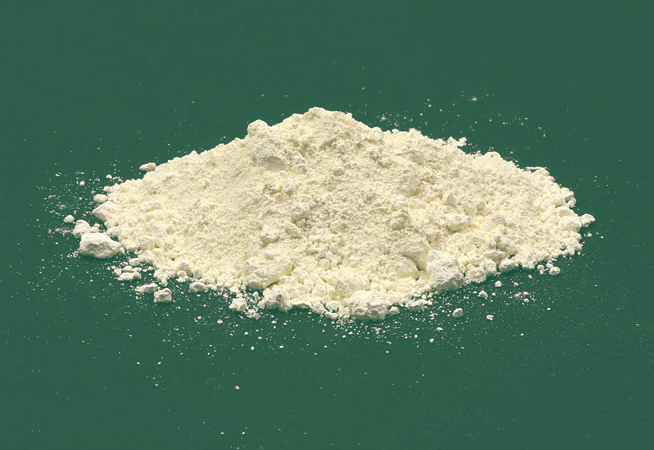

Cerium oxide is a rare earth metal oxide that has a yellowish-white color, a density of 7.65 g/cm³, and a melting point of 2,177°C. It is an abrasive material, thanks to its high hardness, and is soft and powdery. The material is soluble in acids, and it reacts with water to form cerium hydroxide. Cerium oxide has a wide range of applications across industries, making it a versatile material.

Cerium oxide is a useful material with a wide range of applications in various industries. Its unique properties make it an ideal substance for polishing, decolorizing, and clarifying various materials.

Cerium oxide is a widely used polishing powder for a range of materials, including glass, metal, and semiconductors. The soft, powdery substance is easily dispersed in water or oil to create a slurry with abrasive properties stemming from its high hardness. Cerium oxide is effective in eliminating scratches and other surface imperfections.

In many applications, cerium oxide is used in conjunction with other abrasive substances, such as diamond or silica, to achieve optimal polishing results. Additionally, the addition of cerium oxide to a polishing slurry can improve the overall surface finish and decrease the prevalence of surface defects.

Cerium oxide is also used as a decolorizing agent in the glass industry. When added to molten glass, cerium oxide can neutralize the yellow or green tint caused by impurities such as iron, chromium, and nickel. The cerium oxide reacts with the impurities to form a stable compound that does not affect the color of the glass.

The addition of cerium oxide as a decolorizing agent can greatly enhance the quality and clarity of glass products, including windows, lenses, and mirrors. Additionally, the use of cerium oxide can reduce the amount of scrap glass produced during the manufacturing process.

In addition to its use as a polishing powder and glass decolorizing agent, cerium oxide is also used as a clarifying agent in the production of ceramics and glass-ceramic materials. Cerium oxide can remove small particles and bubbles from the molten material, which can improve the optical and mechanical properties of the final product.

Typically, cerium oxide is added to the molten material in small quantities, less than 1% by weight. The cerium oxide particles serve as nucleation sites, prompting the elimination of impurities and the creation of larger, more consistent particles.

The extraction and processing of cerium oxide pose environmental challenges, including the generation of toxic waste and the emission of greenhouse gases. Sustainable and efficient methods of cerium oxide production and use must be developed to minimize its environmental impact.

Cerium oxide is a versatile and essential material in various industries, including glass, ceramics, and semiconductors. Its properties, including its abrasive properties, make it an ideal polishing powder, and its ability to neutralize impurities makes it a useful decolorizing and clarifying agent. However, its production and use must be sustainable and efficient to minimize environmental challenges associated with its extraction and processing. Further research and development will enable the exploration of new applications and expand the potential benefits of cerium oxide in various industries.

For more information about rare earth materials, please visit our homepage.

Eric Loewen

Eric Loewen graduated from the University of Illinois studying applied chemistry. His educational background gives him a broad base from which to approach many topics. He has been working with topics about advanced materials for over 5 years at Stanford Materials Corporation (SMC). His main purpose in writing these articles is to provide a free, yet quality resource for readers. He welcomes feedback on typos, errors, or differences in opinion that readers come across.

Inquiry List

Inquiry List